Finding replacement parts is not often as simple as we would like it to be. This is often the case with machinery that has aged but is still in working order. Yet, there is no reason to struggle with long lead times for OEMs when there are great options for replacement parts.

ROC Carbon’s Replacement Parts

Replacement parts are not one size fits all, rather there are many different options in terms of custom or standardized options as well as material differences to choose from.

Carbon Graphite

If you have been looking for a replacement part you need and you haven’t been able to find one that you can receive in an acceptable amount of time, carbon graphite is a great option. Many people are not familiar with carbon graphite until they need replacement parts. Carbon graphite is a great option for many replacement parts because, when prepared, it offers incredible wear-resistant, high-temperature capability, and self-lubricating properties, and it can be used with corrosive materials.

Carbon graphite can be used to recreate parts to OEM specifications as well as custom specifications. This material has grown in popularity for replacement parts of all shapes and sizes because it can handle dry running conditions, offers great thermal and electrical conductivity, and the above-mentioned benefits. Because of these features, carbon graphite can be used in a wide variety of applications including but not limited to:

- Segmented seal rings

- Bushings and bearings

- Metal backed seal rings

- Mechanical seal faces

- Wear plates

- Washers

- Ball valve seats

- Specialty parts

Carbon machining allows for specifications to be met and new replacement parts to be created even if they are hard to find or not made anymore by the OEM. This is advantageous to many as it allows them to more quickly access the parts they need when they need them, so they can get machinery back online so the bottom line of the business does not need to be impacted long term.

PTFE

PTFE is how most people refer to the material, also known as polytetrafluoroethylene. PTFE is also known in most households by the name of Teflon, which is a brand name of PTFE. This material is a synthetic polymer that is made up of two elements: carbon and fluorine. This material is used in an ever-growing number of industrial applications due in large part to its heat and stick-resistant properties.

There are quite a few characteristics of this material that make it a great choice for many applications. These characteristics include heat resistance, water resistance, it is chemically inert, offers non-stick capabilities, and is highly flexible even at low temperatures. With so many unique characteristics, it can be used in a wide variety of applications including but not limited to:

- Bearings

- Bushings

- Piston rings

- Rider rings

- Seals

- Packings

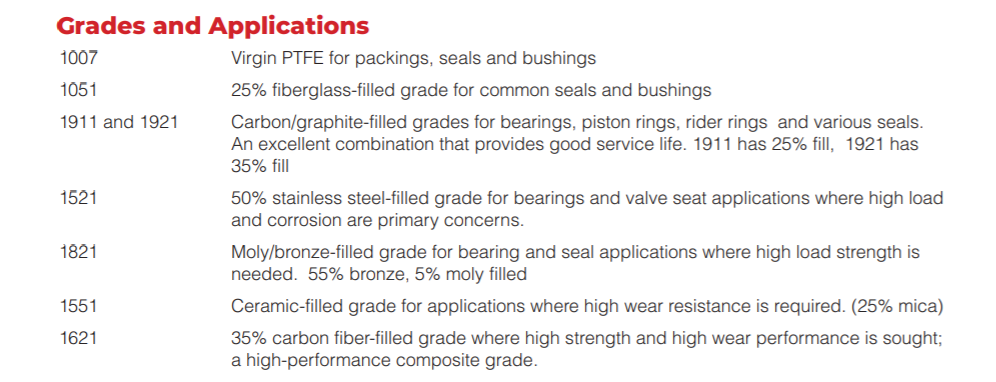

With so many applications and unique characteristics, there are many grades of PTFE that help to ensure that the proper grade is used for each application:

PTFE is quite versatile. With many different grades to choose from, it can be used for replacement parts in a wide variety of industrial applications. Ensuring the right grade of PTFE is used in the creation of replacement parts will extend their life, often beyond what was expected of the OEM.

PEEK

PEEK, officially known as polyether ether ketone, is an organic thermoplastic polymer. It is part of the polyaryletherketone family and is most often associated with engineering applications. PEEK is a semi-crystalline thermoplastic that offers mechanical and chemical resistant properties that are also heat resistant. Many different processing conditions are applied when molding PEEK that can impact the crystallinity of the material, also impacting its mechanical properties allowing for it to be used in a variety of applications.

This material has a variety of unique characteristics that make it quite versatile. These characteristics include chemical resistance, dimensional stability, wear and friction resistance, mechanical strength, and resistance to gamma and x-rays. Additional characteristics include contamination resistance, self-lubricating, and its ability to perform in high vacuum applications.

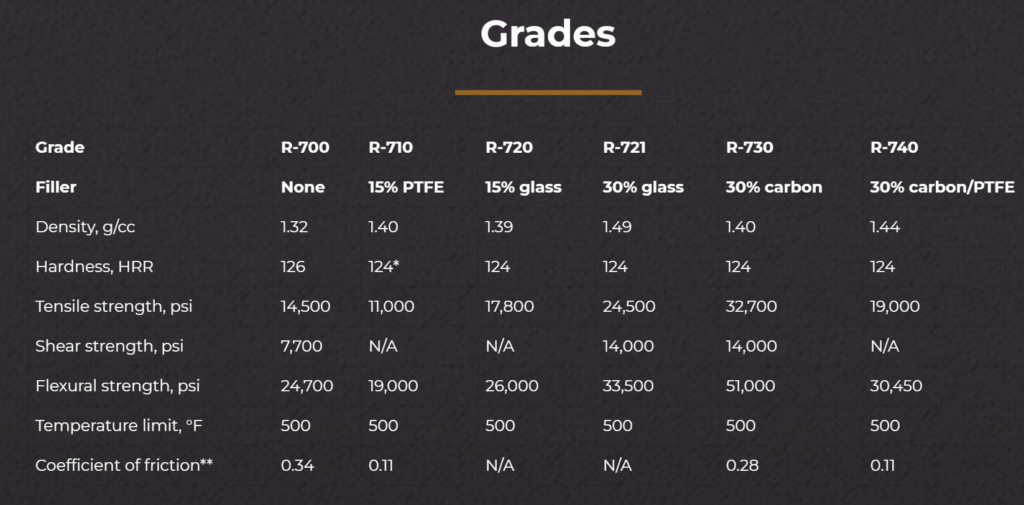

Like PTFE, ROC Carbon PEEK is available in a variety of grades. The grade of PEEK used will be dependent on the application desired:

PEEK can be used in a variety of applications because of its unique characteristics as well as the variety of grades to choose from. The most common applications are oil wells, geothermal wells, chemical applications, nuclear environments, and in the manufacturing of high-pressure valves.

ROC Carbon Wants to Be Your Replacement Parts Resource

Now that you know more about our material offerings, we want to let you know that we want to be your resource for all of the carbon graphite, PEEK, and PTFE parts needs that you may have. With more than 60 years in the industry, we have been able to compile a list of over 20,000 parts and their specifications. When our clients are able to give us a serial number or part number, we can match it to the ROC Carbon part number and ship it out to you immediately, so there is no need to wait weeks for the delivery of a part from an OEM provider.

Do you have a unique part that likely isn’t in stock anywhere? Need a custom part? ROC Carbon can do that, too! We can offer reverse engineering, assuming we have all of the exact specifications. With all of the specifications, we can begin working on your part within as little as two hours, getting custom replacement parts to you in record time, as well!

Whatever the part or material, our goal is always to get it to you as quickly as possible. Since 1956, our goal has been to provide clients like you with the high-quality parts they need when they need them.