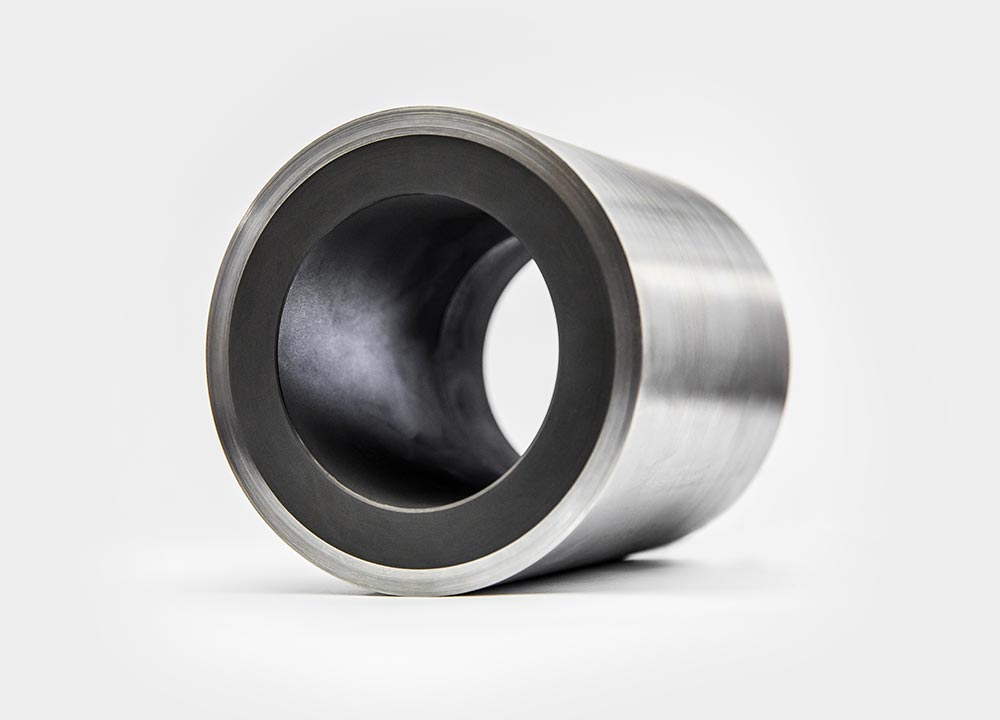

Carbon Bearings, Bushings, and More

Meeting Your Specified Service Requirements

Multiple Styles, Standard, and Custom-Design Options

ROC Carbon self-lubricating bearings and bushings are available in material grades selected to meet the specified service requirements. We provide standard replacement styles as well as custom-designed parts for specific operating problems. Parts range from simple sleeve bushings to more complex styles incorporating notches, grooves or metal reinforced sleeves.

Materials for Carbon Bearings, Bushings, and More

ROC Carbon carbon/graphite materials combine the superior strength, hardness, and wear resistance of carbon with the natural lubricity of graphite. These chemically bonded carbon materials are strong and thermally stable and are inert in most chemical and corrosive applications.

When even better wear performance, higher temperatures, or impervious materials are required, you can enhance the performance properties of your carbon bush bearing through impregnation with resins, metals, and oxidation inhibitors.

Metal-Backed Bearings for Extreme Service

At ROC Carbon, we also manufacture metal-backed carbon/graphite bearings for use in extreme service. The metal selected should have good corrosion resistance, thermal conductivity, or other properties as required by the service. The coefficient of thermal expansion is a factor in metal selection due to the difference in expansion coefficients of metal and carbon/graphite materials.

Press & Shrink Fitting

The method used to assemble the carbon into metal housing depends on the carbon grade used, the metal selected, and the operating temperature. Press fitting is generally used for low-temperature applications, where relatively low interference is needed to keep the carbon from rotating independently.

Shrink fitting is used for high-temperature applications requiring greater interference to prevent carbon rotation. In shrink fitting, the carbon is dropped into a heated metal housing. When the metal cools, the housing shrinks and seizes the carbon.

Technical Services Readily Available

ROC Carbon’s engineering staff is available to help you evaluate carbon bearing bush problems and to recommend solutions involving seal geometry and material. For nonstandard parts for modified machines, we will recommend the proper bore sizes and materials for optimum performance.

Orders

If you need original equipment replacement bearings, simply provide the machine specifications, or a worn part, and the operating conditions, and we will take it from there! We are also happy to design a completely new bearing for you.