In our last blog, Curtis Sager accepted the opportunity to be the next CEO of ROC Carbon and streamlined the warehouse. After several years at the helm, Curtis eventually came to an important realization. Past ROC Carbon CEOs, like his mother Pam Carlson, had been more extroverted and outgoing, and Curtis was not. What would happen if he tried to fit that model and push himself to be an extrovert?

Be True to Yourself

Pam supported and encouraged Curtis. She knew that the differences in his nature and personality made him precisely what ROC Carbon needed from a leader.

In her years as the head of ROC, Pam learned that there must be a balance in all things. This business was no exception. If one CEO is outgoing, perhaps the next should be more reserved.

This forward kind of thinking is what has kept the company so level-headed to this day.

Curtis knew that he could learn on the fly the day-to-day tasks like 401K plans, managing accounts payable/receivable, cash flow, and insurance while he was on the job. His biggest fear and the aspect of the job that created the most anxiety would be learning to work directly with customer problems and pricing issues. As an engineer, this was an area of the business to which he had limited exposure. On the other hand, Curtis was more natural working with employees to solve problems. ROC has always been open and honest, and if you, as an employee, had a question, his door was always open. This openness is a trend that ROC has proudly kept strong.

As we explored in our last blog, Curtis’s goal was to propel ROC into the future with automation. The phrase “automation” is a scary term for workers. Whenever a company introduces automation, it usually leads to layoffs. While workers might see automation as their replacement, Curtis Sager saw it as an enhancement for his workers. A way to build up his employee’s toolbox. Automation for other businesses might keep the status quo. Curtis wanted to use automation to make the work easier for his employees while increasing ROC’s volume.

While the employees love the ease of automation, sometimes those who have been at ROC the longest (almost everyone these days) do remember the “good ole days”. Back when everything was manual and not digital. But today, what was once foreign and strange is comfortable and second nature because, sometimes, we all must take a deep breath, address our fears, and step out into the great unknown.

Curtis learned that he didn’t need to be an extrovert like his predecessors. Instead, he just needed to be himself, and his more introverted and analytical nature is just what ROC Carbon needs. ROC Carbon employees were afraid of the introduction of automation but were pleasantly surprised that instead of being replaced were actually getting an upgrade in the warehouse. The automation process has helped the ROC workers successfully fulfill the 24-hour turnaround promise.

Stay tuned for another fun chapter in our History blog series coming next month. In the meantime, this month’s featured product: ROC Carbon’s excellent customer service.

ROC Carbon’s Customer Service

There would be no ROC Carbon without our wonderful clients and customers. Our customer service is as impeccable as our custom seals and bushings. We could brag about ourselves all day, but the best boast comes from the source – our clients.

Here is an excellent story from Industrial Parts Specialties, whose plant had shut down and was not operational. Facing being closed for another week, they decided to move forward with repairing a key component. IPS had materials on hand to make the repairs, but a critical bushing was dropped and shattered. IPS called ROC in a panic on a Saturday. They calmly picked up their part 24 hours later and were up and operational that Monday. How did they describe their service?

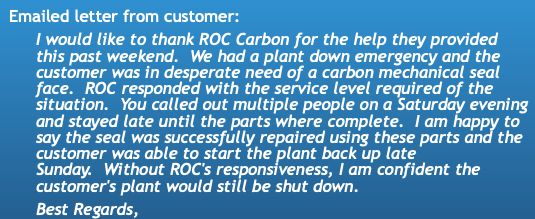

Another Example of our Customer Service

Another client had their plant come to a complete stop on a Friday and desperately needed a carbon mechanical seal face. They called. We answered and responded by calling in multiple people on a Saturday evening. ROC Carbon stayed late until their replacement parts were completed. Our clients were happy to say that we successfully repaired their seal, and our client’s plant was back up that Sunday evening. All within 24 hours. ROC Carbon’s doors are ready to custom manufacture your parts day or night.