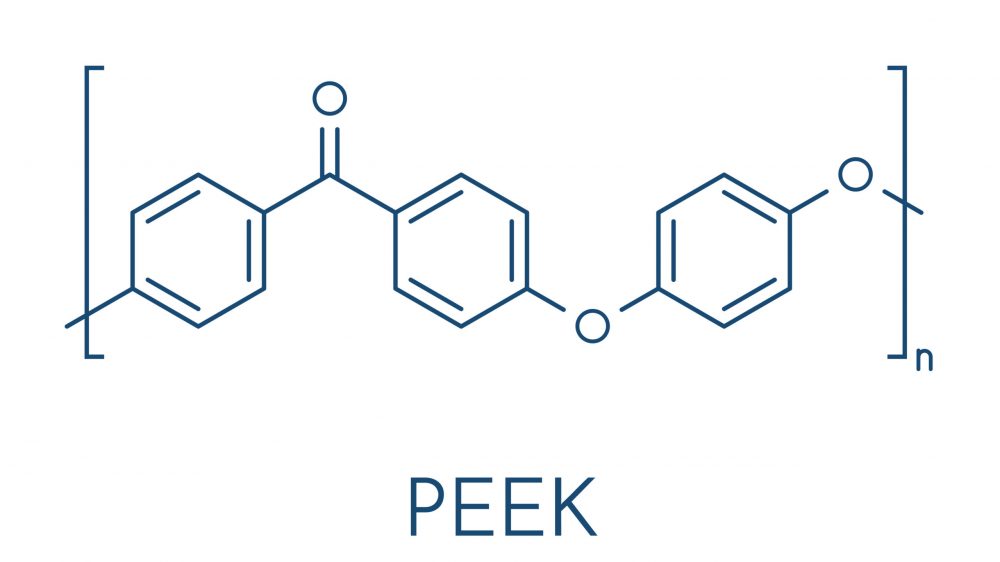

At ROC Carbon Company, we have found that PEEK is a wonderful material for many different parts and applications. PEEK, also known as polyetheretherketone, is a semi-crystalline thermoplastic. It is a polymer that belongs to the polyketone family of polymers such as PEK, PEEKK, PEKK, and PEKEKK. PEEK is the most commonly used and manufactured in this family of polymers.

Why PEEK?

While it’s not appropriate for every application, it has many benefits that make it a great option.

PEEK’s popularity stems from its exceptional combination of mechanical, chemical, and thermal properties, making it suitable for a range of demanding applications. Some key features of PEEK include:

High-Temperature Resistance: Exhibits excellent resistance to high temperatures, allowing it to maintain superior mechanical strength and stability even at elevated temperatures. This property makes it ideal for applications in aerospace, automotive, and electrical industries, where exposure to heat is a concern.

Chemical Resistance: Provides remarkable resistance to chemicals, including acids, solvents, and hydrocarbons. This resistance ensures the material’s durability and integrity in harsh chemical environments, making it suitable for applications in chemical processing, oil and gas, and medical industries.

Mechanical Strength: Possesses exceptional mechanical properties, including high rigidity, toughness, and wear resistance. It exhibits low friction and excellent dimensional stability, even under heavy loads and in harsh conditions. These attributes make it well-suited for applications such as gears, bearings, seals, and structural components.

Electrical Insulation: PEEK is an excellent electrical insulator, making it widely used in electrical and electronics applications. Its electrical properties remain stable across a broad temperature range, enabling reliable performance in challenging environments.

But there are even more reasons to choose PEEK:

- Exceptional tensile properties. A tensile strength of 29000psi is achieved when reinforced with carbon fibers.

- Excellent creep resistance. This polymer provides an excellent balance of properties that enable it to withstand high loadings for long periods at high temperatures without permanent deformation.

- Offers flexural modulus at very high temperatures and can be improved with glass or carbon reinforcement.

- High volume resistivity and surface resistivity. This polymer maintains good insulating properties in a board temperature range.

- This polymer has very low smoke and toxic gas generation.

- Insoluble in all common solvents.

- Good dimensional stability

- Exceptional insulation properties

- Excellent sterilization resistance at high temperatures

- Long life

- Inherent purity

- Biocompatible

As you can see, PEEK has some really great characteristics that make it attractive for various purposes. Of course, it does have some limitations, such as expense, issues with UV tolerance, and the need to process at high temperatures.

At ROC Carbon Company, the use of this polymer in various parts and applications is a testament to its versatility, reliability, and performance across industries requiring high-performance materials.

ROC Carbon Company Can Assist With Your PEEK Needs

ROC Carbon Company is equipped to assist you in determining the most suitable material for your parts needs. Whether it is PEEK, PTFE, carbon graphite, or other materials, we can craft parts tailored to your specifications with precision and expertise.

At ROC Carbon Company, we can help you determine if this is the right polymer for your specific needs. If it is the right material choice, we can get started on crafting your parts needs immediately. If there is a material that suits your needs better, we can tell you that. Since 1956, we have been working with PEEK, PTFE, and carbon graphite materials. ROC Carbon can assist you with all of your parts needs.