Welcome back ROC Carbon Family! In today’s installment, learn all about how the ROC Carbon family leaned on each other and their faith to keep going strong after tragedy. Keep scrolling down to learn more about our metal backed components and how they can help save your products!

After the untimely passing of the ROC Carbon patriarch, Mrs. Dody Ricks had two choices: close up shop or pick themselves up and soldier on. Like any great company, the team rallied behind their leader.

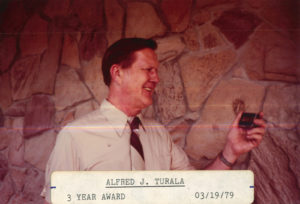

While utterly devasted, Dody knew that letting a 20-year project in the making fall to the wayside was not an option. She pushed on as long as she could, but as fate would have it, she put her company in the hands of her faith. When the time came to retire, she had a neighbor who, coincidentally, had a friend looking for a small family-owned company that wanted to grow. Al Turala knew ROC Carbon had been through some hard times but that it was a company worth saving.

Little did they know that this chance encounter would set up the company for generations to come!

After their meeting, the first thing Al set out to do was look over the company and set up a path forward for the company. Before even stepping into the CEO’s shoes, he knew he would need an eventual replacement.

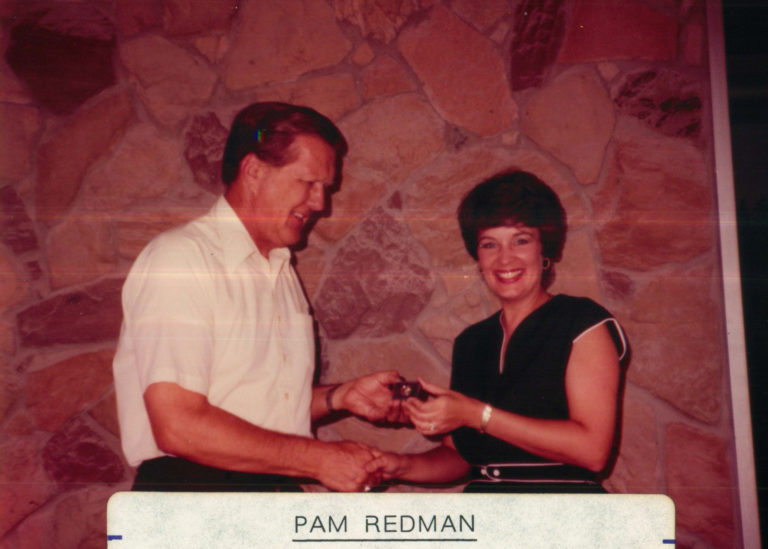

Al took one look at Pam and asked, “how would you like to run the company someday?” Pam jumped at the chance. Actually, she replied, “no way! I love being in HR! I love working with the people!” but Al knew that Pam was the future, so he made her a compromise, and this is where Al showed his ingenuity. He said, “I don’t want you to make your decision based on what you know right now because I will work with you. I’ll teach you what I’ve learned and help you grow in this area.” He knew that where we are today isn’t where we will be tomorrow, let alone ten years down the road.

To Be Continued…

Metal Backed Type Bushings

Bushings made with a metal backed components sleeve have several advantages over our standard carbon bushings. First, the metal sleeve can offer protection to the housing if there is an upset event that damages the carbon bushing. The sleeve becomes an easily replaceable sacrificial element, allowing the bushing to be easily replaced without performing repair work on the housing.

Next, installing any carbon bushing requires an interference fit between the housing and the carbon. A skin cut on the bearing bore is usually necessary to ensure it is perfectly round. This may be very difficult to machine, due to the housing size or the bushing location in the equipment. Our MB type bushing is more tolerant to a slightly out of round bore than the standard carbon bushing, and the press-fit of the sleeve into the housing is less than the standard carbon bushing. This allows the bushing to be installed without additional machining and without the need to heat the housing to install the bushing.

Metal Backed Type Seals

ROC Carbon Metal-Backed Components type seals are manufactured to precise tolerances for high-speed compressor and gas turbine applications. Adding a metal sleeve to the OD of the carbon seal provides support to stiffen and strengthen the seal. Also, because the sleeve is placed on the seal with an interference fit, the clearance between the shaft and ID of the seal is very close to constant as the operating temperature increases.

Because of the tight manufacturing tolerances, larger seals are fitted with an ID plug to help maintain the roundness of the seal during shipping and storage. This plug is removed prior to installation.

Lapping is also available for the sealing faces after the parts are finished machined.

ROC Carbon precision manufactures our MB-type components to provide high performance for bushing and sealing applications.