Have you been frustrated with the amount of time your team spends searching for OEM parts, especially carbon graphite parts? This is a huge frustration for many business owners when their machinery is offline, and they need a replacement part. When your machinery is down, you’re losing money. In any industry, if you’re not online, you’re losing money!

Many OEMs’ slow response times mean you are losing money waiting for the parts you need. Instead of jumping through hoops with an OEM and having your production stalled, why not consider custom carbon graphite parts? These can be made to your specs and in your hands in just a couple of days, saving you time and money.

Quick Access to Carbon Graphite Parts You Need

While ordering from your OEM has long been the standard, it often is not the most effective option. There are often long lead times for receiving the parts that you need, and when you are offline, you are losing money.

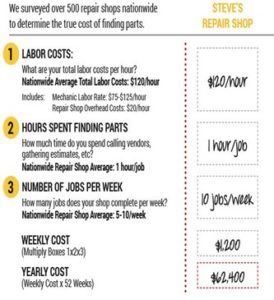

The time you spend searching for the parts you need is also costly. Most businesses initially shy away from the idea of custom carbon graphite parts because they worry about the added expense. Yet, when you break down the long lead times that can keep you offline, and the amount of time you spend searching for the parts you need, you will find that you are already spending more on OEM than you realize.

When you order custom carbon graphite parts, you’ll have direct access to the manufacturer. You’ll be able to discuss your exact needs, and you can even specify if the order needs to be rushed. If you have drawings or serial numbers, the parts can often be made for you starting in just a couple of hours’ time and can be shipped to you so you can get back online within days.

This quick access to the parts that you need, when you need them, is worth any cost increase for the actual part. Yet, when you stop and think about it, the part isn’t necessarily more expensive because you are saving on downtime and part search expenses.

Quality Assurance

The term custom is often associated with a higher price because a product is made specifically for you. There is also an implied quality assurance that gives the buyer peace of mind. This is not to say that OEM is not a good quality product, but many buyers find that a custom product offers an even higher level of quality than OEM.

Custom carbon graphite manufacturers know that they have to offer tight quality control standards to keep customers returning. This dedication to quality has many business owners choosing custom parts over OEM because they know that not only will they get the parts that they need promptly, but the parts will also be impeccably made.

Made to Your Specs

Another great reason to buy custom carbon graphite parts is that they can be made to your precise specs. Do you have parts that the OEM no longer provides or are readily accessible? If you have drawings, serial numbers, or measurements, custom parts can be made to get your machinery back online, even if you cannot easily access the parts from the OEM.

Even if you are not sure what type of material the part is, custom parts providers can determine this for you and recreate the part with relative ease. Well-cared-for machinery will often last longer than the OEM is willing to offer new parts. This is great on one hand because it means you are extending the investment in the machinery, but it can be frustrating when you can no longer order the parts that you need. Custom manufacturers are a reliable solution to this often frustrating problem.

Ensure Durability and Performance

Many business owners find that the same parts fail in their machinery. This happens for a variety of reasons, and most of them are due to parts wearing over time. Did you know that you may be able to have parts custom-made to be even more durable so you can increase performance and longevity? When you order from a carbon graphite parts manufacturer, you can discuss your concerns about how your parts are wearing.

Knowing the application, the manufacturer may be able to suggest carbon graphite impregnated with other materials (like resin and metals) to ensure durability. Many business owners are happy to spend more on a custom part built to withstand specific conditions, as it will likely outperform the part from the OEM.

ROC Carbon Wants to Be Your Custom Carbon Graphite Manufacturer

Experience matters. Since 1956, we have been working with businesses like yours to keep our client’s production online. We know that every part need is unique and that time is money. Over 60 years, we have perfected our approach to providing our clients with the high-quality parts they need when they need them. Do you have a straightforward need? ROC Carbon has you covered. Do you need some reverse engineering, or would you like to consider an impregnated material to improve part performance? ROC Carbon can do that, too!

We have thousands of different parts in our system that can be made for you when you call us, or we can work off your drawings. Our goal is to provide you with the highest quality parts that you need as soon as possible.