If parts procurement is a regular task, you know that it is not always easy. Depending on your application, it may be challenging to find an OEM with readily available parts or are of the quality that you require. Then, even when you find the parts, getting them in a reasonable amount of time can be nearly impossible. Your replacement part manufacturer can considerably impact the parts procurement process.

Quality Matters

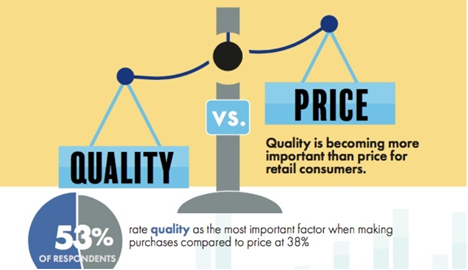

The internet is a great tool; in seconds, you can find answers to your most pressing questions and find vendors who sell just about every product you could ever imagine. What the internet doesn’t do for you is vet the quality of the information or the products. But quality matters. Most buyers would agree that quality is more important than pricing, as quality parts will last longer and perform as expected, allowing you to get your money’s worth.

When you are procuring parts, you should ensure that you are getting parts that live up to the strictest standards and perform as expected. A worthwhile manufacturer of your replacement parts will provide the piece is made from the highest quality materials to your exact specifications. Is your current parts vendor doing that for you?

Speed Matters

When you need parts, you need them now. When ordering consumable parts, you usually have a general idea of how long they will last. This gives you some lead time to order new products, so you have them on hand for regular maintenance. But what about premature failures? Non-consumable parts that fail spontaneously? If you don’t keep these products on hand, and many of us wouldn’t, you need parts quickly. Does your current parts provider process your requests quickly?

The cost can be astronomical when you have a part fail, and production stops. It impacts profitability, the supply of your products or service to those who purchase them, not to mention the impact it has on the morale of your staff.

Is your current supplier able to get your orders to you quickly? Having a parts manufacturer that understands the need for speed will help you minimize your downtime costs. While there may be a delay if the part must be reverse-engineered or custom-made, the turnaround time should be days, not weeks.

Service-Oriented

Do you ever feel that you are nothing more than a number with your current parts vendor? Is your current supplier expecting your calls or following up with you when it has been a while since they heard from you last? This feeling can be frustrating because it clarifies that you are nothing more than the money you spend with them. When looking for the ideal parts supplier, you should feel that they take the time to understand you and your unique needs. Having a supplier in touch with your individual needs can make all the difference.

ROC Carbon Wants to Ease Your Frustration

Since 1956 we have been working with clients from various industries, all with their unique needs. ROC Carbon understands that the needs of all of our clients are unique to their industry and their application. ROC listens to what they need and suggests how to ensure success with parts, and we are always looking forward to their next order. WE don’t just fulfill a need; we build relationships with our clients so they know that they can depend on us to craft the quality parts they need when they are required.

As a business ourselves, we understand that quality, timing, and dedication to service make all the difference. We can quickly craft standard parts when you call, but we happily take on more significant challenges with reverse engineering. Our goal is to prepare what you need when you need it.

Are you ready to relieve your current frustrations with lack of supply, lack of quality, slow delivery times, or the lack of service? ROC Carbon Company would love to show you our customer-centric approach with quality and speed at the forefront at all times.