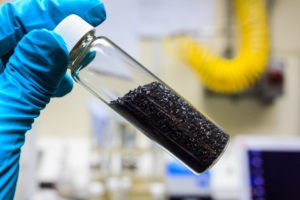

If you are like most people, you may not have been familiar with carbon graphite until you needed a replacement part such as a turbine ring, metal-backed seal ring, or something similar. This material is a popular choice for crafting specialty parts because the material boasts a combination of strength, hardness, and wear resistance while offering natural lubricity not seen in other materials.

Carbon Graphite’s Lubricity and Versatility

Carbon graphite is often the material of choice because it offers a natural lubricity not seen in other materials. Where lubrication is concerned, carbon graphite outperforms traditional oil lubrication. For instance, an oil-lubricated bearing would struggle at temperatures less than 40 degrees Celcius because of the high viscosity of the oil. Yet, the traditionally oiled bearing would struggle at temperatures over 200 degrees Celsius because the oils carbonize and become abrasive. Carbon graphite bearings would be effective at both temperatures and can perform well in both wet and dry conditions because the material has natural lubricity.

Ability to Impregnate

Carbon graphite is a wonderful choice for specialty parts because it can be impregnated with a wide variety of resins, metals, and oxidation inhibitors to make it even more versatile. With proper machining and manufacturing, it can be used to create the most obscure, out-of-stock, or even out-of-production parts safe for a wide range of applications.

ROC Carbon Wants to Be Your Carbon Graphite Specialty Part Manufacturer

Ready to experience the versatility and benefits of specialty parts? ROC Carbon would love to help! If you need a part that can’t seem to be sourced from the OEM, or you just want to try something new, don’t hesitate to request a quote. We only provide the highest quality specialty parts made to your exact specifications. Contact us today or download a brochure to learn more about our products and services.