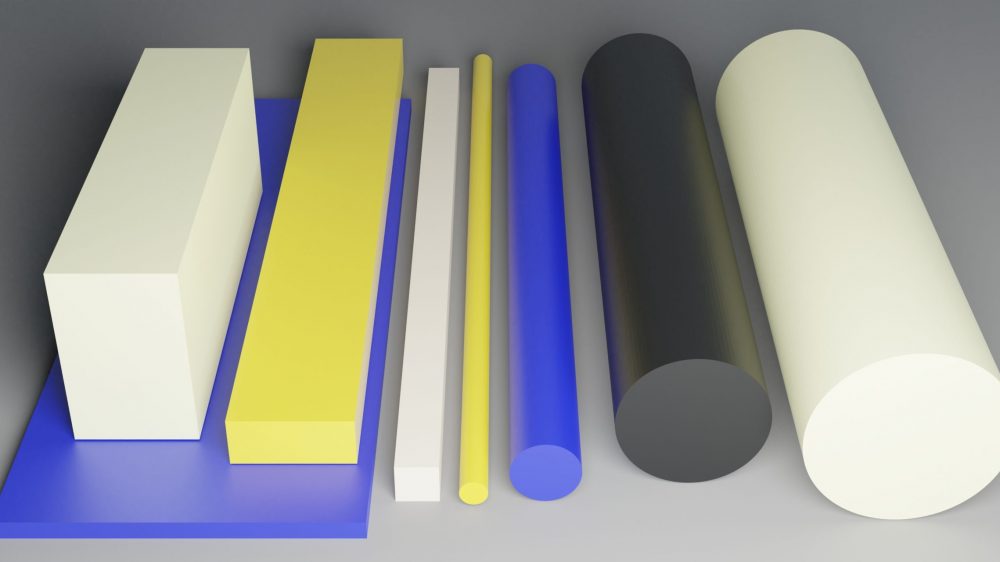

When looking to replace parts or investigating materials used in the parts in your machinery, you may come across the term PTFE quite often. Understanding what this material is and its applications can help you discern if it is the best material for your applications and, further, what grade of the material is correct for your use.

PTFE: What is it?

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It is known for its exceptional chemical resistance, low friction properties, and high-temperature stability. These characteristics make it a versatile material with various applications across different industries.

Characteristics and Applications

PTFE is used in a variety of applications because it boasts some unique characteristics. One prominent attribute of PTFE is its excellent non-stick properties, which is why it is commonly used as a non-stick coating in cookware such as frying pans. In fact, the general public likely has PTFE in their home as a brand name many are aware of —Teflon.

The characteristics that make this material unique include but are not limited to:

- Heat resistance. PTFE has outstanding thermal stability and can withstand high temperatures. This property makes it advantageous in applications that involve extreme heat or cryogenic conditions. This material has a melting point of 327°C so there are very few applications where it can be damaged by heat.

- Water-resistant. Polytetrafluoroethylene is resistant to water making it useful in a wide variety of applications. Due to its exceptional water resistance, PTFE is commonly used in industries where exposure to water or moisture is a concern. Its ability to repel water and resist absorption makes it suitable for applications where maintaining material integrity in wet conditions is critical.

- Chemically inert. PTFE is resistant to most corrosive. It is highly inert and resistant to a wide range of chemicals, acids, and solvents. This makes it useful in industries involving chemical processing, pharmaceuticals, and electrical insulation.

- Non-stick. The coefficient of friction associated with PTFE is one of the lowest of any solids known. Meaning that virtually nothing will stick to it.

- High flexibility. Polytetrafluoroethylene (PTFE) is known for its flexibility even at low temperatures, allowing it to maintain its structural integrity when subjected to extreme cold. This flexibility is attributed to PTFE’s unique molecular structure, which enables it to remain pliable and resistant to cracking or stiffness in cold environments. As a result, PTFE can be applied to surfaces or used in applications where flexibility at low temperatures is essential without compromising its performance.

Applications of PTFE

There are many applications associated with PTFE. The grade of the PTFE used will depend on the application:

-

- 1007 – Virgin PTFE for packing, seals, and bushings.

- 1051 – 25% fiberglass-filled grade for common seals and bushings.

- 1911 and 1921 – Carbon/graphite-filled grades for bearings, piston rings, rider rings, and various seals. An excellent combination that provides good service life. 1911 has 25% fill. 1921 has 35% fill.

- 1521 – 50% stainless steel-filled grade for bearings and valve seat applications where high load and corrosion are primary concerns.

- 1821 – Moly/bronze-filled grade for bearing and seal applications where high load strength is needed. 55% bronze, 5% moly filled.

- 1551 – Ceramic-filled grade for applications where high wear resistance is required. 25% mica.

- 1621 – 35% carbon fiber-filled grade where high strength and high wear performance are sought; a high-performance composite grade.

Why ROC Carbon’s High-Quality PTFE

ROC Carbon is proud of our ROCBON high-performance, reinforced fluorocarbon composites. Our products possess exceptional properties, including chemical resistance, self-lubricating, thermal stability, moisture re-sorbent, contamination resistance, mechanical strength, and electrical insulation. We have been working with this material for many years, and like our other products, we are dedicated to creating the parts you need in the fastest turnaround time possible.