This blog post is the first in a new series detailing the history and development of the ROC Carbon Company. We are thrilled to be sharing this peek into our company’s past and hope that you’ll join us for the entire series as our story unfolds! After you read about the start of our fantastic journey, make sure to keep reading about our wonderful featured product of the month. This month, learn about our custom turbine rings.

ROC Carbon Company started in 1956 when Morgan Ricks realized that he could provide valuable services to the oil and gas refineries in his area of the Texas Gulf Coast.

In those days, Mr. Ricks worked from his garage in Houston, TX, and drove to the nearby refineries to understand first-hand what these businesses needed most. He found out that when the refineries needed parts for steam turbine repairs, speed was essential to keep their operations on track! With this knowledge, Mr. Ricks built a business model that is still the foundation of his company 65 years later.

The company grew rapidly thanks to word of mouth, great performance, and a lot of hustle from Mr. Ricks. In the 1950s, refineries and chemical plants relied on large storerooms full of spare parts for the repair of industrial equipment. To address their needs, we created large catalogs, or “surveys”, with part drawings, OEM part numbers, and customer part numbers. Making a call to a refinery back then meant opening drawers, counting parts, measuring, and making part drawings on the fly! Back at the garage, Mr. Ricks developed a proactive “Rolodex” system to provide information for the parts that were needed and a manufacturing plant to provide quick turnaround parts for all the refineries in the area.

It didn’t take long at all before Mr. Ricks’ company outgrew his garage. He and his wife, Dody, purchased five acres of land on the west side of Houston, where they built a 10,000-square-foot manufacturing facility. In the blink of an eye, that facility grew to a 30,000-square-foot manufacturing plant, with offices attached to handle the increasing demand for ROC Carbon parts.

A strong company depends on its ability to continually assess the risks and opportunities that lie ahead. On March 1, 1977, Morgan Ricks passed away. Suddenly, Mrs. Ricks faced the daunting challenge of navigating the company without her husband at her side.

We’ll share her story, and that chapter of ROC Carbon Company’s history, in this series’ next installment.

Did you enjoy this story?

Want to see more blogs like this one?

Featured product: ROC Carbon Turbine Rings

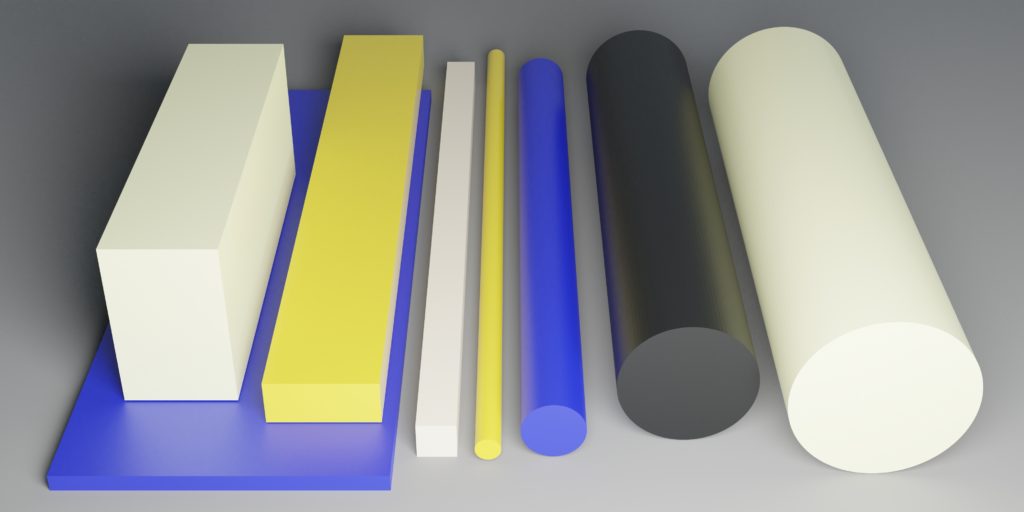

ROC Carbon Company manufactures custom turbine rings for hundreds of steam turbine models that are currently in production, as well as for older models that are no longer manufactured by OEMs.

We custom-size your turbine rings by using operating steam temperature and shaft size to calculate a clearance of .001” at operating temperature.

The material ROC uses is a fine grade of graphite that handles high-temperature service conditions with unparalleled longevity of use!

Our precision manufacturing method maintains the accuracy of each segment and, when assembled, creates a “light-tight” finished product for superior sealing.

ROC Carbon uses Inconel for the garter springs surrounding the segmented seal ring to ensure high performance at an elevated temperature. If a different material is needed for the spring, we will custom-make the spring to meet your service needs.

What sets the ROC Carbon Company apart, and the standout feature that our customers know they can rely on, is ROC’s ability to deliver your custom turbine rings with same-day shipping!